The EU is taking climate protection very seriously. Both increasingly stricter environment and climate protection regulations and rising costs through emissions trading are turning up the heat for the industry. By 2030, greenhouse gas emissions in the European Union are to be reduced by at least 40 percent compared the corresponding levels from 1990. By 2050, they are to be cut by as much as 80 to 95 percent.

This affects the steel industry in particular, given that it is considered to be one of the main industrial sources of the climate-damaging gas carbon dioxide. As a result, European steel producing companies are trying to fundamentally change their manufacturing processes through a number of pilot projects and test facilities in order to reduce these unwanted emissions.

‘Hybrit’ – a game-changer for the traditional production process

The joint endeavours of a project of three Swedish companies, the steel group SSAB, the mining group LKAB and the energy group Vattenfall, are already coming along swimmingly. ‘Hybrit’, short for ‘Hydrogen Breakthrough Ironmaking Technology’, is set to produce zero carbon steel from 2020 onwards. At a plant in Luleå in northern Sweden, the conventional production method is being given a dramatic facelift.

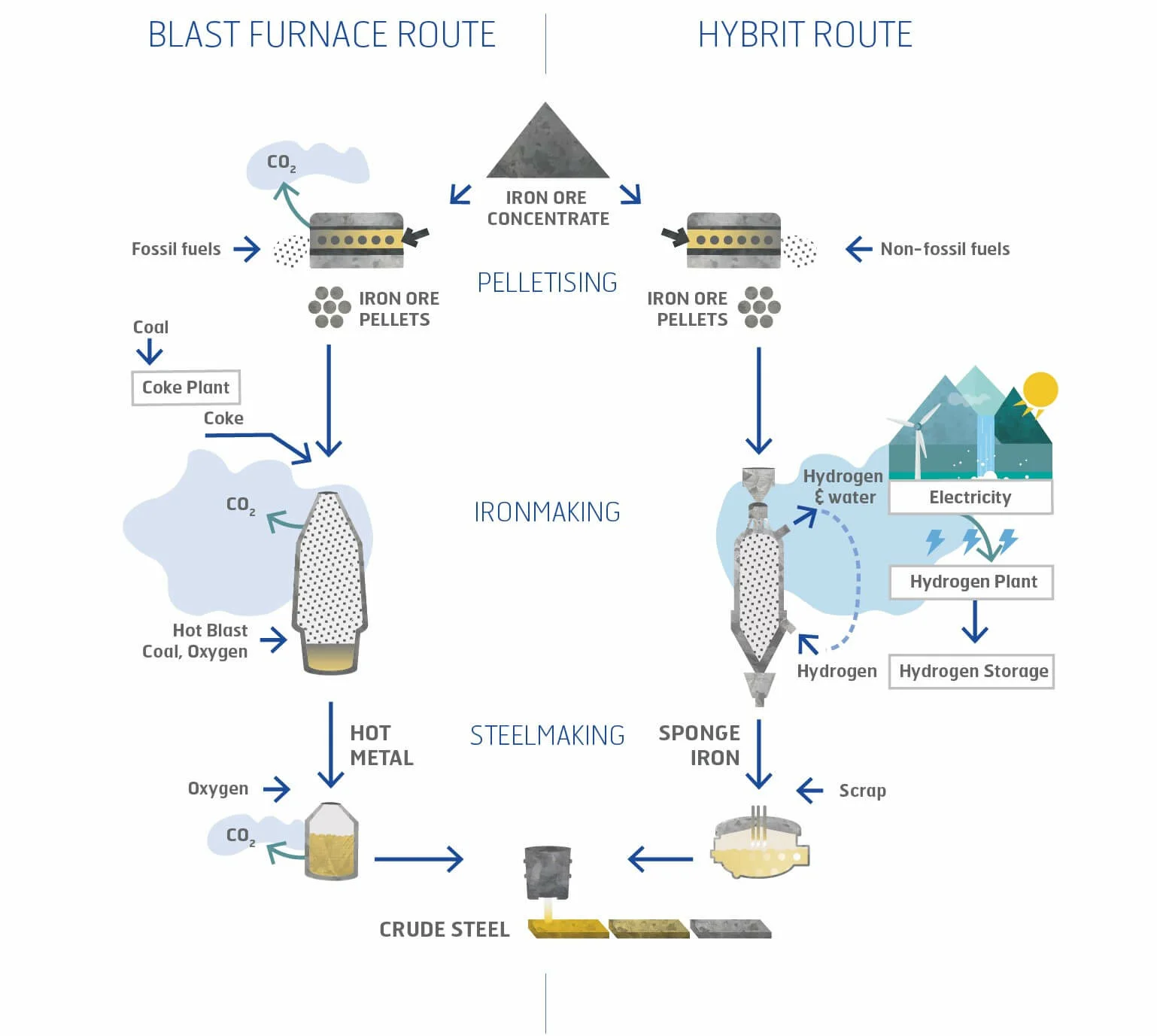

The production of pig iron, which is later made into crude steel, uses iron ore as a basic material together with what is referred to as a reducing agent, which removes oxygen from the iron ore. Traditional pig iron manufacturing processes usually use coke as a reducing agent. However, in doing so carbon and oxygen produce the climate-damaging gas carbon dioxide.

Video explaining the function of Hybrit

The aforementioned new production process uses hydrogen instead of coke, which also reacts with the oxygen in the iron ore, but the result is water vapour rather than carbon dioxide. The hydrogen itself is produced climate-neutrally with electricity from renewables. As such, the process could ultimately produce genuinely ‘green steel’.

Hydrogen process to drastically reduce emissions

The Swedish Energy Agency has calculated that this process could reduce the CO2 emissions of the entire country by up to ten percent. It is supporting the development of the plant, which is costing around 150 million euros, with a subsidy of 50 million euros – according to the agency, this is the largest amount of funding ever allocated.

Initially, Hybrit will only produce a comparatively modest amount of one metric ton of steel per hour. Moving forward, however, production is to be expanded to churn out the usual industrial quantities of around 100 to 200 times this figure. According to the feasibility study, the associated costs are currently still 20 to 30 percent higher than those of the traditional process, mainly because hydrogen production is complex and energy-intensive. However, according to Mårten Görnerup, who heads up the project, this price tag should also become competitive by 2035. He bases this forecast on the fact that emission certificates will become significantly more expensive in coming years, while renewable energy will be available at increasingly affordable prices.

Blast furnaces in Duisburg to be extinguished by 2050

In Duisburg, things aren’t quite as far along as in Sweden. Thyssen Krupp Steel has created a ‘Roadmap for hydrogen-based steel production’, as Andreas Goss, Head of the Steel Division, explained to Handelsblatt earlier this year. All blast furnaces at the Duisburg-Bruckhausen site will have been extinguished by 2050 at the latest. Before then, the group plans on investing ten billion euros in the development of processes for zero carbon steel production.

Special reduction facilities, rather than blast furnaces, will be needed for the hydrogen process. This is why Thyssen Krupp is planning on slowly upgrading or replacing existing facilities with new ones. The company is still in the process of looking into things, and Dr. Arnd Köfler, head of production, sees “many unanswered questions” in the supply of hydrogen.

New blast furnace replaces coking plants

In the Netherlands, Tata Steel Europe, Europe’s second-largest steel producer, is testing another way to reduce emissions from steel production. According to the group, the production of one metric ton of steel at the Ijmuiden plant currently creates 1.7 metric tons of carbon dioxide. This is significantly less than other plants (which emit around 4 metric tons of CO2), but is also very close to the absolute baseline of what can be achieved with current production process.

The group considers the opportunities in this area to be exhausted – significant reductions are only possible through the development of “groundbreaking new technologies”. One such technology could be what is known as the Hisarna process. Back in 2010, a plant based on this process was built at the Ijmuiden steelworks to the tune of 20 million euros. Since then, millions more have been invested and a number of test runs have been carried out.

A state-of-the-art cyclone-converter furnace is at the heart of the process, and reaches temperatures that allow direct feeding of iron ore and coal. Normally, the materials would have to be prepared before processing – with the help of this new furnace type, this is no longer necessary. “This process significantly reduces the number of energy-intensive steps required for the conventional steel-making process,” the company says. This also reduces energy consumption and emission levels. While in the beginning there was talk of “at least 20 percent” less CO2 emissions, long-term testing has shown that it could in fact be as much as 50 percent. According to the company, a plant is currently being planned that will use this process to produce liquid iron on an industrial scale. It will be operational in about seven years.

Which process is ultimately adopted across the board remains to be seen. A current study of the Fraunhofer Institute for System and Innovation Research initiated by the European Commission has come to a similar conclusion: emissions in the EU could be reduced by 95 percent through “innovative CO2-neutral technologies and far-reaching technical changes”. The steel industry has taken the first steps. ‘Green steel’ could one day become a reality.

Photo credits: OVKNHR, shutterstock.com